| completed hip rafters |

|

Pillars

supporting the front Wings

The pillars are connected to the poles by hip rafters, completing the Temple's skeleton.

|

The Pillars Genesis

My original idea for the pillars which support the front wings of the roofs outer skirt was to use 4"X4" hardwood posts.

When the walls were finished and I realized all the earth building tools were soon to disappear I decided the pillars would be better to match the walls and be made of earth.

We had one week to make the foundations and build the pillars. Which meant the council would not be able to get involved with the amendment as we had to move quickly.

The pillars each sit on a tapered octagonal concrete plinth 1mX1mX1m with a 300mm above-ground 600mm diameter collar - this meant we could use the formwork vertically.

|

|

Relief work on the pillars |

| the footings - 1 for for each pillar |

|

Back to basics

First we had to excavate by hand 2 deep and wide holes to support the pillars.

As these would not be connected to the main foundations they needed to be deeper and wider than the trenches we had dug for the main footings.

|

More “decorations”

Although pressed for time we managed to add some symbol relief work to the forms before pouring.

more symbols were added to the base |

|

|

|

the formwork was harder to remove |

Ready for the earth

We included 3 cyclone rods to hold down the top plates, the front verandah beam and the hip rafter.

The holes (each about a cubic metre) were filled with wheelbarrows during a fairly frenetic half-hour.

|

|

a pillar's base - ready for the earth |

| Relief work on the pillars - the Tree of Life |

|

The Pillar's decoration

Trijntje was still in Sydney at this time and I had 3 days while the concrete cured before it would be ready to build on.

I knew we were going to have to use some oregon planks inside the formwork to convert a square space into the octagonal one which would match the Temple's shape.

An idle-mind: it became clear that here was an opportunity to decorate the pillars and add some character, but I had to work fast.

With little time to spend on creating a design, Celtic knot work seemed ideal for the surface dimensions and a speedy carving job.

I spent the time marking out the knot work and routing the 4 X 3m-long oregon beams . One pair bore the tree of life from the Book of Kells and the other a more contemporary design in keeping with the octagonal theme of the building.

I was advised that the relief work probably wouldn't work for a variety of reasons which did sound plausible at the time.

|

the experiment worked!

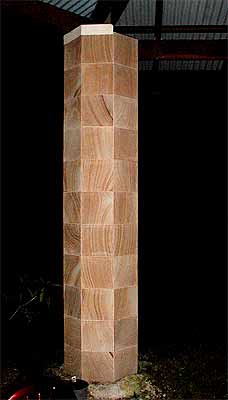

These photos were taken shortly after the pillars emerged from their formwork.

The earth is still quite moist as it needs to be for the ramming to work best.

This is the octagonal design I put together to dress a face of the pillar and blend the ancient style with the modern building.

The concrete collar the earth sits on has its own relief work and inlaid semi-precious gemstones and slices.

I was well-pleased with the results and thought they would be a fine addition the the Temple.

|

|

Relief work on the pillars |

| With the roof on |

|

With the roof on

Later on - there's the roof

It was all starting to become quite cosy.

|

|

|

The story doesn't stop there

Rains arrived in November, 1998 which was to prove the start of 8 months of wet weather. January 1999 was particularly abundant with three days of solid, driving torrential rain. The exposed faces of the pillars suffered 3 days of water constantly running down them. Eventually the moisture penetrated beyond the surface sealing and was sucked in , causing the earth to swell.

|

CyberSayer spoke of disaster . . .January, 1999

During the rain, the software I was working on - a digital oracle, was harping on the subject of disaster.

During the rain Trijntje went for a walk in the long sodden grass. She returned ashen-faced and in an obvious state of shock.

This was the site which had greeted her >>>>>>>>>>>>>>>>>>>>

Over large areas the outer 20-30 mm was cast off as a serpent shucks outworn skin. I still shudder to look at these pictures - but - see what we ended up with - it's an ill wind as they say, silver linings etc etc

John and Gabor of Rammed Earth Constructions were similarly stunned and they committed to fixing it immediately.

I believe the culprit was a clay particle in one of the soils which reacted with the earth bonding emulsion and perforated the surface bonding creating openings for the water to soak in.

|

|

a sobering site to see |

| rendered pillar ready to face |

|

Restoration waits .... and waits

The pillars were defaced with mattocks and rendered with a sand/cement mixture. The result was somewhat less attractive.

We decided to face the pillars with sandstone - it took 7 months for the weather to relent sufficiently to undertake the work.

|

The task was long and finicky - each tile had to be drilled top and bottom for stainless steel locating pins and hooked into the render.

|

|

construction detail |

|

| The tiles ready for grouting |

|

September 1999:

3 courses of tiles held together with the pins and ready for grouting.

<<<<<<<<<<<

>>>>>>>>>>>>

The first pour of grout blew 2 tiles off

- we wondered when the disasters would end!

|

|

tiles ready for grouting |

Some Silver Lining!

|

|