|

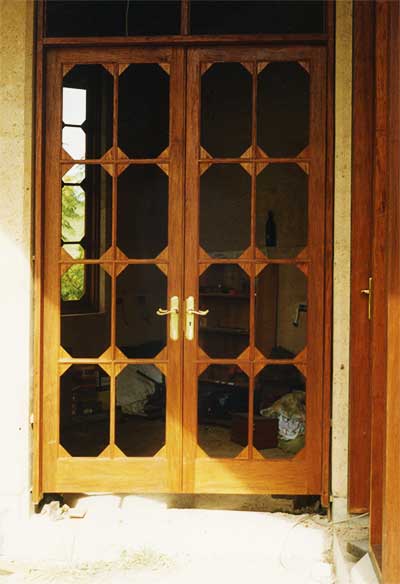

Doors doors doorsand windows

The timber used throughout is New Guinea Rosewood - Sustainable Timbers of Maleny recommended this as being sustainably harvested in the Solomon Islands.

|

is reminiscent of a hall of mirrors. |

you can see the gap beneath the door which would later be filled with cement, sandstone and brass. |

The Hanging

The doors are quite large and, once glazed would be quite heavy, so we hung the doors and windows before they were glazed.

|

Draught Exclusion

During the design considerations I have absorbed the idea that a welcoming building has the doors opening inwards - it makes sense to me that when you answer a door knock the guest isn't pushed away by the opening door.

|

|

|

A Technological Solution

The inward-opening doors were a challenge to make draught proof whilst avoiding the obvious solution. I eventually decided to use brass sills to create a uniform flat surface under the door and seal the gap with inserts of nylon-brush strips which are used in sliding aluminium windows for draught-exclusion.

|

|

back to the ceiling |

top of this page |

home page |

next are the floors |

|

|

return to top of this page |  |